Design of Offshore Structures and Types Of Offshore Oil and Gas Production Structures

Offshore Structures Definition

Offshore Structures Definition - Offshore construction is the installation of structures and facilities in a marine environment, usually for the production, oil, gas and other resources. Generally, all offshore platforms have:

- A superficial structure, mostly above the water level consisting of operations, machinery, accommodation, control systems, piping systems, etc.

- An intrinsic underlying system consisting of drilling equipments: drill bit, drill collar, risers and conduits, wellheads for the purpose of extraction of oil from the sea bed

Different Types Of Offshore Oil and Gas Production Structures:

- Floating Offshore Production Systems: Semi-submersibles and Drill ships are designed to remain afloat hundreds of miles in deep waters. Though floating in nature, they are also a type of permanent oil production systems.

- Tension leg platforms (TLP): TLP structures are also a part of the floating production systems which a capable of providing buoyant production facilities. They are moored to the sea bed via the tendons fixed vertically to the structure. The foundation of TLP’s intricate mooring pattern is kept stationary by piling.They experience more of horizontal stresses due to waves as compared to the vertical movements which are restricted by the tendons fixed to the foundation. These structures are able to drill at depths beyond 5,000 feet and are more stabilized as compared to the other ultra deep water drilling units.

- Spar Platforms: For drilling wells beyond 10,000 feet, naval architects have designed a type of drilling and production platform which has a hollow cylindrical hull that can descend upto a sea depth of 200 meters. This are called Spar Platforms. It is secured to the ocean floor by a complex network of cables and tendons.The weight of the cylindrical hull stabilises the drilling platform and caters for the drilling risers to descend upto the drilling well on the sea floor.

- Subsea Production System: As the name suggests, this system is based on the idea where wellheads are mounted on the sea floor after the wells have been drilled by one of the many deep sea drilling platforms.The wellheads are remotely controlled and their automated system is so designed that it allows for transporting the oil or gas directly to the production facilities using a network of undersea pipelines and risers.

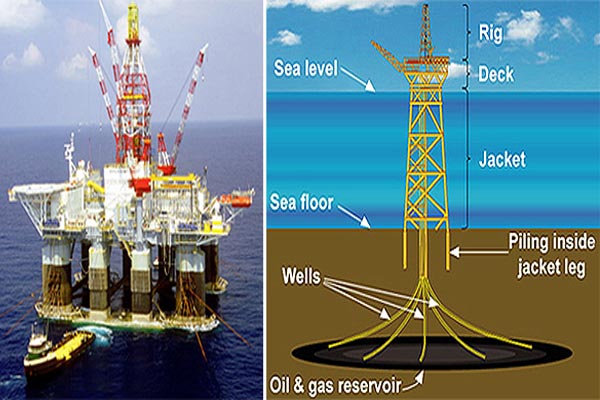

Parts of an Offshore Platform

An offshore platform deals with topside facilities as well as the underlying drilling facilities. The topside facilities lying above the sea level involves an optimization between space as well weight yet involves all the neccesities for the oil extraction purposes. The ambient components of any offshore platform involves derricks, drilling rigs, oil storage facilities and tanks, injection compressors, gas compressors , gas turbine generators, HVAC, Piping, Instrumentation, Basic machinery like primary and auxillary power generators, cooling system, pressure regulation etc. Also worth mentioning are control wheelhouses for operating personnel, suitable accommodation and helipads. Cranes and lifting system for loading and unloading operations are also there.

In the undersea extraction systems, some of the terms worth mentioning are drill collars, drill bits, wellheads, conduits, risers, BOPs, etc. Though not complicating stuff about the details and description of each of these, drill bits and collars involve drilling into the sea bed to create the oil well for extraction. On the other hand, wellheads provide structural and pressure containing interface at the opening to any oil or gas well for drilling and production.

Risers are components synonymous with any drilling platform inherently. This is basically a conduit that provides an extension from wellhead subsea to the drilling system above. They are basically of two types: marine drilling risers for floating platforms or tie-back drilling risers for fixed platforms. Risers have the catalytic role of conducting the crude oil or gas from the wellhead to the drilling rig by the virtue of a piston like mechanism which in turn is sent to the above rig for processing. The design of the riser depends on the filed layout, vessel interface, fluid properties and environmental conditions. Risers maybe flexible or rigid. Also they remain stable and in tension due to self weight. They may have profiles to reduce excess load and nonviscous fluid flow.

Mooring and Anchoring

Given the varying sea conditions and the environmental vagaries, for proper positioning, ease of operation and safety , mooring facilities have to be initiated. Mooring may be by the virtue of steel or synthetic mooring lines. Steel ropes having high strength and rigidity have catenary nature and may use more length. On the other hand synthetic mooring lines are elastic, taut -shape and uses lesser length.

|

| Sumber: lshipdesign |

Also corrosion is a big setback for stell ropes as compared to the synthetic ones. The platform may also be under certain conditions be anchored or held fixed to a jetty or pier if possible. Drillships, FPSOs or sometimes semi-submersibles mostly use DPS (Dynamic Positioning Systems) systems for positioning.

Loads on any offshore Structure

Any offshore structure can be subject to various loads like:

- Permanent Loads

- Operating Loads

- Environmental Loads

- Construction

- Accidental Loads

Permanent loads involve the construction loads like the weight of the entire structure, ballast systems, weight of machinery, accomodation and other equipment. For members below the waterline it involves the hydrodynamic forces and also the hydrostatic pressure forces like the buoyancy and pressure loads.

On the other hand, operating loads involve the loads subservient under the ongoing operations like loading and unloading, drilling, mooring operations, additional loads generated by cranes and derricks.They take into account impact, momentum, vibration, slosh dynamics, material fatigue etc. Also involves weight of manpower,equipment, storage like the crude oil which has been extracted, life-support systems and so on.

Environmental loads may be subdivided into the various categories like:

- Wind Loads: These loads act on the above portion of the platform by virtue of the blowing winds of varying extremities.For instance during regular sea breeze, this aspect is not to be taken care of but where the situation is graver like in case of gale storms ruffling the seas hither and tither, the consequent aftermath on the structure is a pressing concern. Especially when height to width ratio is more than 5, the cyclic wave loads due to the induced vortex flow has to be taken seriously into account.Structural members have to be designed such that they can withstand longitudinal loads with greater endurance than transverse for higher slenderness ratios.Snowfall or frost heaving which is a phenomenon of abnormal swelling of soil during cold temperature may pose a potential threat to the structure.

- Temperature and Atmospheric Pressure loads cause thermal expansion, contraction and sometimes deformation. Suppose a platform amidst the cold northern Atlantic during winters have ti endure high amount of low pressure and temperature vagaries while somewhere near the Tropics during summer, it may be subjugated to high temperatures, pressures, humidity or warm underwater currents sometimes leading to expansion.

- Seismic Activities often take place in the underwater oceanic plates where they drift, vibrate, intimate or recede away from each other. These oceanic seismologic behaviour which often leads to climate change and variance in the ocean wave mannerisms have a detrimental impact. Sometimes these oceanic activities pave way for catastrophies like the Tsunami which may be fatal.

- Lateral Loads from soil , groundwater or seabed may endanger their piling or foundations hence often aggravated by seafloor scour.

- Wave loads are the most prominent terror that poses threat to all offshore structures. The ceaseless oceanic activities at the surface from light ripples to gigantic waves are a matter of vast study which I do not include in this article. Only I would mention that the waves are basically gravity contact forces energy transfer phenomenon that occurs due to wind pressure on the water surface with a given force or speed, duration and fetch(distance over which the wind blows). Waves may be of internal or external type or maybe normal sea waves, swells or breaking waves.Technically, the total wave forces on larger, broader structures maybe through diffraction theory while that of slender bodies with D/L ratio greater than 0.2 and considered hydrodynamically transparent use Morrison's equation for calculating wave impact. Thus the preliminary design of any offshore structure takes care of its resilience to the waves it faces.

- Marine growth accumulates on the submerged surfaces, increasing the wave forces through higher drag forces and surface roughness.

Installation Loads

These are temporary loads that arise during the fabrication or erection of the platform or its components. During fabrication erection lifts of various structural components generate lifting forces, while in installation phase, forces are generated during platform load out, transportation to the site, launching and upending, as well as lifts related to installation.

All lifted system loads may be suited to withstand the loads of the material as well as sustain the static equilibrium of the lifted component, the slings in tension and the entire system. Other forces involve the drag forces to a jacket when transported from the fabrication yard to the site or tugging a completed semi-sub by a Heavy lift ship. Also another crucial aspect taken into account is the final "fixation" of the structure like in case of a jack-up plunging its legs to the sea-bed, or while mooring a semi-submersible or while merely clamping the legs of a jacket platform to the sea-bed through piling foundations. These activities often generate terrible heave motion which unrestrained may lead to operational failure or even collapse of the structure.

Accidental Loads

To err is human. If we go by these words in our day-to-day lives, such multi-purpose projects are not out of the bag. According to DNV, accidental loads are loads which may occur as a result of pure accident or exceptional circumstances. So, the worst instances may be collision, breakage, flooding of buoyant parts, fire or explosion. Since the majority of offshore platforms deal with oil, gas , petroleum which are inflammable storage and productions needs to be with umpteen care. Evacuation measures need to be implemented in case of the unwarranted.

Fire extinguishers and proper recovery equipment should be handy to combat any hazard and revert to the recovery process as fast as possible.

This was all about design considerations for offshore structures which every offshore engineer is always aware of. The next time we will take a look at the different types of offshore structures in existence. Oh, and before leaving, do not forget to follow the youtube link for an exciting documentary on these 'Megastructures'.LSD

Thank you for reading Design of Offshore Structures and Types Of Offshore Oil and Gas Production Structures on blog Marine Engineering

Reference: marineinsight.com

I genuinely prefer to perusing your post. Much obliged to you such a great amount for setting aside the effort to share such a decent data. I'll unquestionably include this extraordinary post in my article area.

ReplyDeleteAutomated Vision Inspection Machines

Oil well drilling drill pipe wiper balls can wipe cement, fluids, debris, and separate liquids from drill pipes and tubing. You can use them to wipe drilling fluids and displacement fluids of any kind.

ReplyDeleteFluids can be separated using drill pipe wiper balls and drill tubing and drill pipe can be removed of cement, fluids, and debris.

These drill pipe wiper balls are made from natural rubber and are temperature-resistant from 40°F (4°C) to 302°F (150°C). It can bend between 380 and 440%, so even small obstructions won’t be damaged.

Email: meritautomotive@gmail.com

Drill Pipe Wiper Balls

Drill Pipe Foam Wiper Ball

Drill Pipe Wiper Foam Balls

Merit DP Wiper Ball

Merit DP Wiper Balls

Drill pipes or tubing connections can easily accept our wiper balls, and multiple balls can be pumped if necessary. It passes easily through mechanical setting tools, diverters, and liner running tools.

In order to prevent scale from sticking to the ID of the drillpipe or workstring, wipe it with foam wiper balls. As a fluid separation measure and to facilitate sheath removal, foam wiper balls may be pumped behind cement.

インドとベトナムのオフショア開発者の専任チームを雇う。グローバルジャパンネットワークは、柔軟な採用モデルでオフショアソフトウェア開発サービスを提供しています。#1 オフショア 開発 台湾

ReplyDeleteオフショア 開発 と は